Home builders who have been struggling to obtain key building materials such as lumber and cement now face an even more urgent priority – an acute shortage of glass for windows and doors.

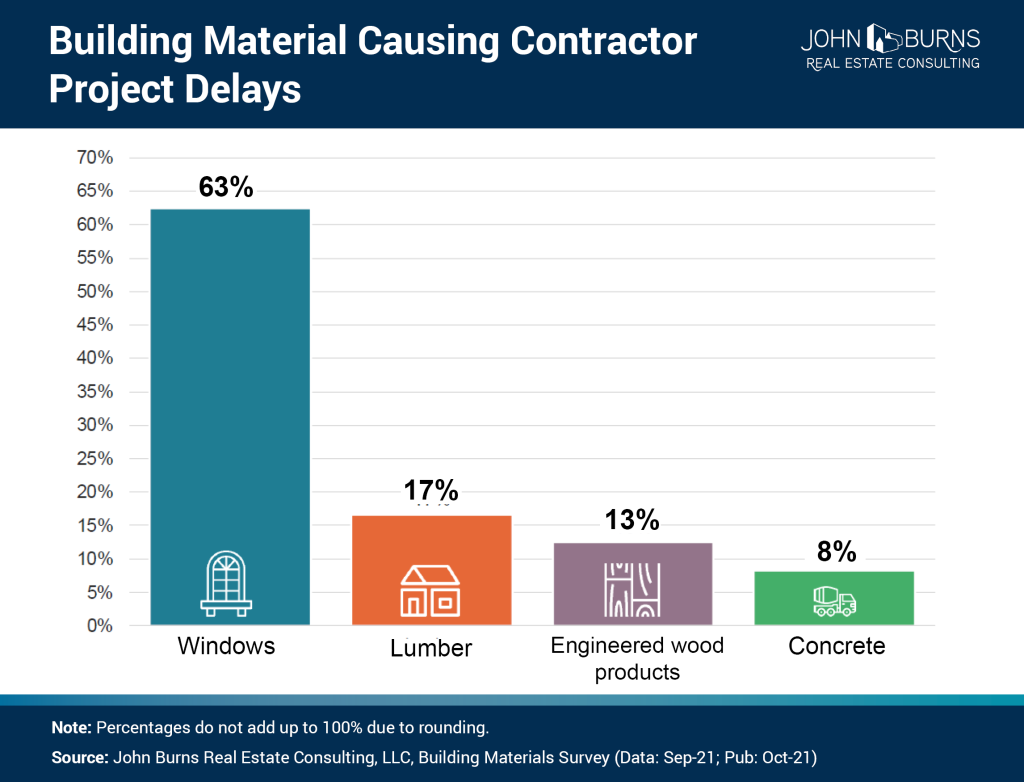

An October survey by John Burns Real Estate Consulting found that windows are now the major supply challenge for 63% of home builders. Shortages of lumber, engineered wood products and concrete are still problematic, but affect less than 20% of builders, the report found.

The average lead time for windows currently ranges from between four and 15 weeks, while certain kinds of windows have lead times of 20 to 45 weeks, the report found. Before the coronavirus pandemic, average lead times were typically just two to three weeks.

While the shortage of glass is a challenge for some window manufacturers, the bigger problem is a lack of skilled labor. According to the report, window manufacturing, even in the most automated factories, is incredibly labor-intensive. The industry has therefore been hit by labor shortages due to COVID-19.

“Most window manufacturing facilities rely more on labor and less on capital than other building material manufacturers,” the report stated.

The lack of skilled workers was cited by two major U.S. firms – the Venice-based impact resistant door and window manufacturer PGTI and Californian-based Cornerstone – in recent earnings calls. They say hiring of manufacturing labor is a key focus area in the near-term, Business Observer reported.

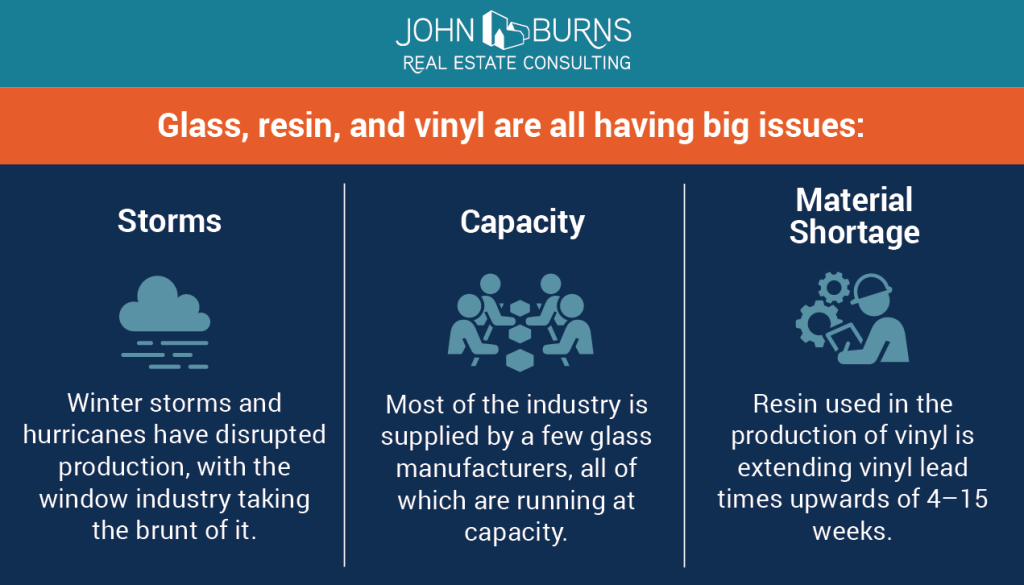

Supplies are an issue for window manufacturers too. Winter storms in Texas earlier this year caused disruption to the production of key resins used in windows and shortages have persisted ever since. Later, Hurricane Ida reportedly damaged refineries and chemical plants along the Gulf Coast, adding to the industry’s woes. Resin is a key ingredient for the production of vinyl, and some vinyl producers have reported delays of up to five months.

The shortages have resulted in dozens of U.S. glass manufacturers putting customers on allocation.

Due to this, many glass manufacturers have shifted production overseas to countries such as China, Mexico and India. However, that hasn’t been enough to make up the difference, with glass shortages also affecting the supply of bottles and jars, leading to price increases for some grocery products.